- All

- Product Management

- News

- Introduction

- Company Branches

- FAQ

- Company Video

- Company Album

Forming machine

Category:

Keyword:

Details

Full hydraulic system

Full hydraulic system

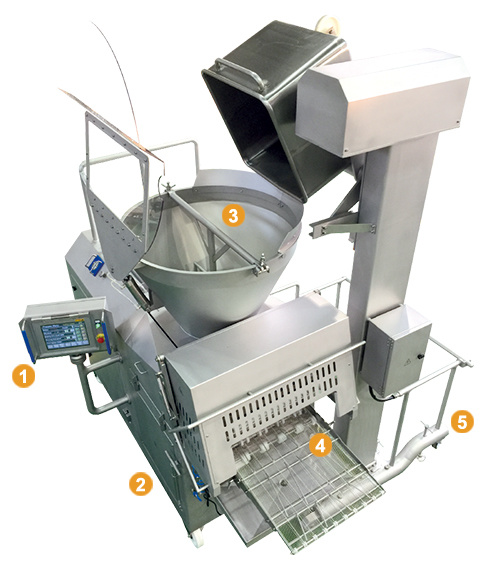

Forming Machine ProForm®

Diversified products such as chicken nuggets and patties can be molded with less friction.

- The propeller feeding method is adopted to transfer the raw material particles to the forming mold while maintaining the state of the raw material particles

- The raw materials transferred to the forming mold are blocked by the half-moon valve to prevent backflow to the hopper

- Swing-arm 12.1 inch colorful wide touch-screen improves simplicity and awareness

- The water spray system can be operated in a ratio according to the process conditions, greatly reducing the water consumption (option)

- Check the temperature of the hydraulic oil from time to time, and initiate an alarm when an abnormality occurs

- The hydraulic system has a simple structure and can be easily maintained by unskilled technicians

- The frame of the meat car hoist adopts an arc structure to reduce foreign matter residues

Humanized operation control

- 12.1 inch colorful touch-screen is the basic configuration

- 20 processing recipes can be stored and read

- Process parameters can be edited, searched and modified at any time

Safety

- All hydraulic systems, cylinders and drives are configured inside itself

- All components of the hydraulic system are separated from the product processing area, so as to make the processing safer and more hygienic

ProForm® Parameters

|

Model |

ProForm® 600CL |

|

Hopper volume |

235 Liters |

|

Stroke/min |

6-55 |

|

Touch-Screen |

12.1 / 15 (Opt) |

|

Length of Mold |

150 mm |

|

Width of Mold |

570 mm |

|

Thickness of Mold |

50 mm |

|

KW |

17.38kw 23.25hp |

|

Cooling way |

Wind cooling |

|

Water cooling |

15.75kw 21hp |

|

Capacity |

2,500 kg/hr |

Without notice in case of technical parameter’s modification

Previous Page

Next Page

Previous Page

Next Page