- All

- Product Management

- News

- Introduction

- Company Branches

- FAQ

- Company Video

- Company Album

Smoked furnace

Category:

Keyword:

food machinery

Details

SteadyGen®

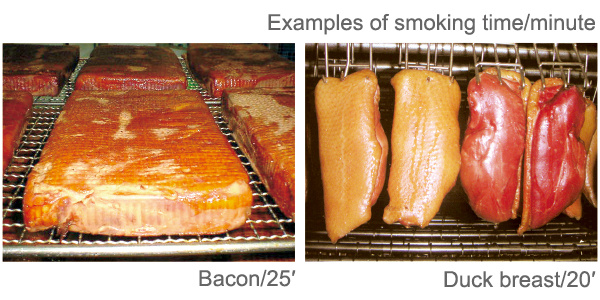

Smoked furnace with a new LS type smoke machine

- The world adopts smoke concentration measurement and control, and put it into application on the microcomputer controller to execute the short-time smoking process

- The world adopts smoke concentration measurement and control, and put it into application on the microcomputer controller to execute the short-time smoking process

- Significant drying effect improves the yield and stabilizes the smoking process

- High-density smoke machine with reduced wood pellet usage

- No excessive smoke oil

- The smoking process time is short, and the yield rate is high

- 99 programs can be recorded or read

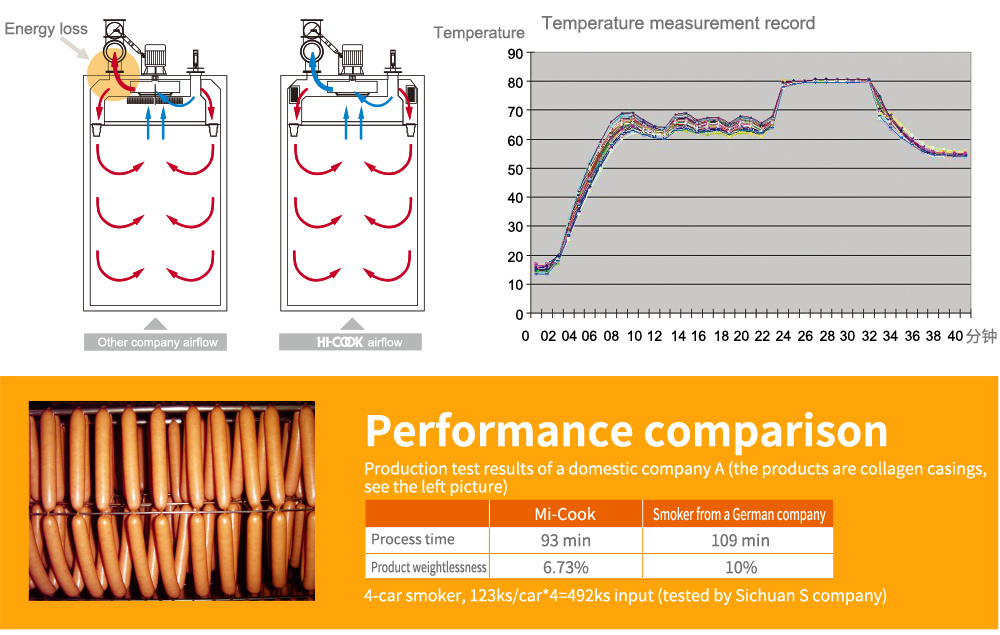

- Reduce heat-exchange energy loss

- The energy piping is centrally connected directly above the furnace for easy maintenance

- With CIP cleaning system

- 200 degree high temperature conditioning processing can be carried out through electric heating or gas burner device (optional)

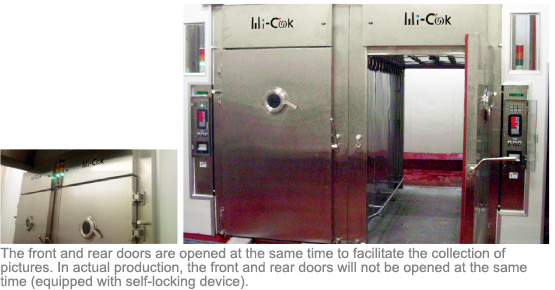

- Equipped with in-furnace see-through windows and inspection windows on smoke machine

Channel

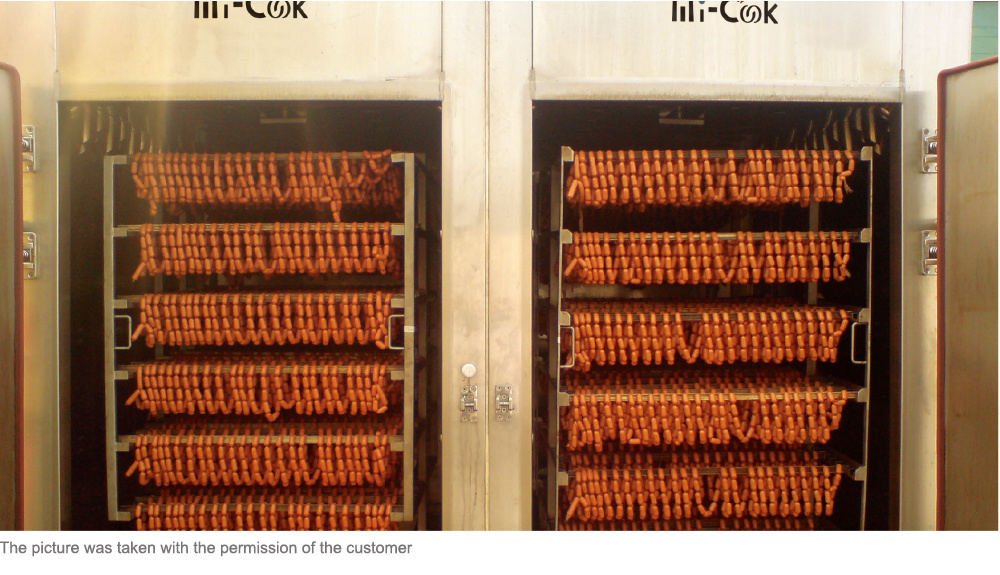

Smoked furnace

With the layout of the production workshop, the channel type is more effective

Mi-Cook tunnel smoked furnace has passed the inspection standards for heat treatment facilities in overseas food processing plants by the Ministry of Agriculture, Forestry and Fisheries of Japan in Japanese export processing plants in many Asian countries such as China, South Korea, Thailand, etc.

Energy saving and even heat distribution

Previous Page

Next Page

Previous Page

Next Page