- All

- Product Management

- News

- Introduction

- Company Branches

- FAQ

- Company Video

- Company Album

Double spiral steamed roasted machine

Category:

Keyword:

food machinery

Details

Double spiral steamed roasted machine

Double spiral steamed roasted machine

As a leader in the manufacture of industrial-grade steamed and roasted equipment, the various thermal processing equipment of Mi-Cook has made rapid progress and development in how to improve the C flavor and how to increase the yield rate in the past half a century. For those users with greater production capacity, Mi-Cook double spiral steaming opportunity will bring them unprecedented surprises. The double spiral steamed roasted machine combines the advantages of the ZFO and MB series baking machines. At the same time, the vertical flow and the horizontal flow can be freely converted, and the conditioning conditions can be independently controlled to process various products. The main frame of the body is designed as an octagonal structure, which can reduce the internal hot air circulation resistance and heat loss.

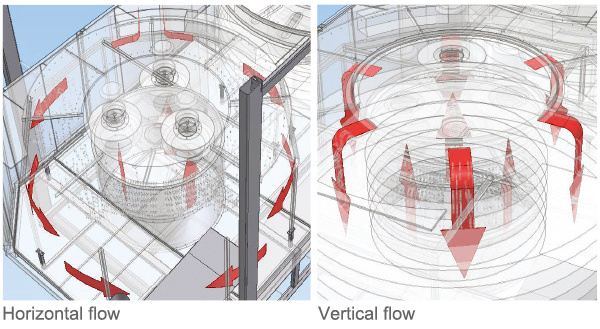

Mixed air flow control

The horizontal flow based on deep-temperature pasteurization and the vertical flow based on surface coloring are combined in one system and can be used after converting easily.

In the two conditioning drums, horizontal flow and vertical flow can be selected separately, or the same air flow can be selected for conditioning.

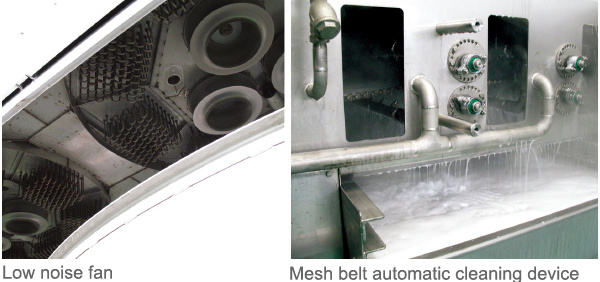

Low noise circulation fan

High-speed circulation of high temperature (270℃) hot air can achieve lower noise during operation under resistance.

The reduction of noise means less vibration of the entire equipment, which can ultimately extend the service life of the overall equipment.

High energy efficiency of octagonal structure

The internal frame adopts an octagonal structure, so that the hot air can circulate naturally without resistance inside the toaster. While the internal volume of the octagonal frame is reduced as a whole, the time required for the internal temperature to rise and the amount of energy consumed are also reduced.

Previous Page

Next Page

Previous Page

Next Page