- All

- Product Management

- News

- Introduction

- Company Branches

- FAQ

- Company Video

- Company Album

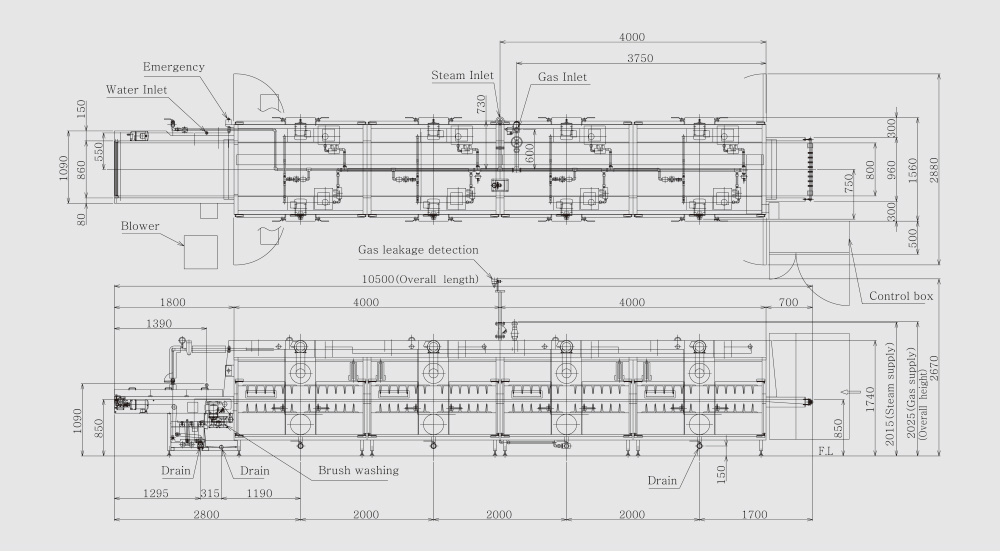

Steam combined micro-jet steaming machine

Category:

Keyword:

Details

Super high-speed airflow with a fragrant and juicy effect

Super high-speed airflow with a fragrant and juicy effect

Steam combination

Micro-jet steaming machine

The hot air impact method is used to heat the processed products at ultra-high speed. The hot air stream directly heats the product surface directly under high pressure and quickly accelerates the heat exchange. That’s the new concept type, continuous micro-jet baking machine.

- There is no temperature difference between processed products. The impact blowing method is used to uniformly heat the entire width of the conveyor belt to avoid temperature differences. Further improve the safety and processing reproducibility of deep-temperature pasteurization of products

- Suitable for a variety of new product development

- The upper and lower floors are equipped with independent fans, and the air volume of the upper and lower floors can be controlled separately according to the product processing requirements to achieve different barbecue effects

- The temperature, time, wind speed, etc. can be set through the touch control panel

- Preliminary operators can also simply operate through the stored process number buttons

- Ignition sensing, flame detection, abnormal overheating detection, abnormal conveyor belt operation, door opening state sensing and other devices are all standard configurations

- The front and rear doors of the cabinet are spring-loaded, which can be fully opened during cleaning. The impact blowing air duct is detachable, easy to clean

- The whole is made of stainless steel, which can be washed and hygienic

Previous Page

Next Page

Previous Page

Next Page