- All

- Product Management

- News

- Introduction

- Company Branches

- FAQ

- Company Video

- Company Album

Pasteurizer

Category:

Keyword:

Details

Continuously

Pasteurizer

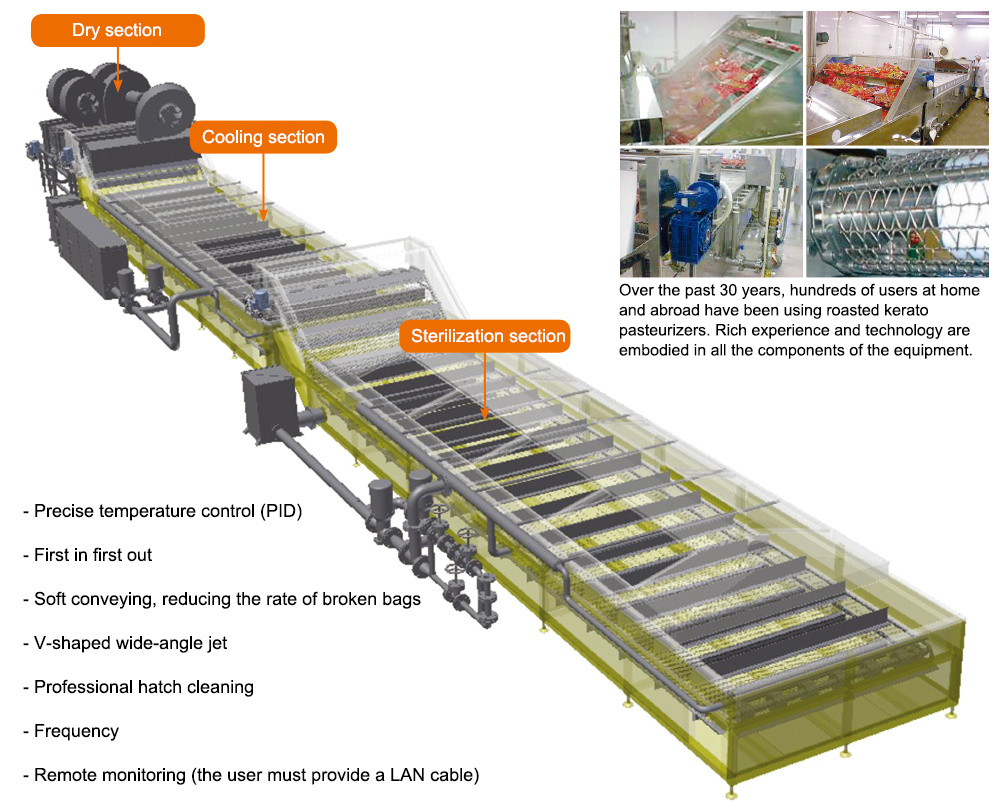

Mi-Cook are with vacuum packaging products, instead of aseptic packaging products. In the packaging process, bacteria and microorganisms are bound to invade. Therefore, it is particularly necessary to sterilize in a short time, otherwise the product quality will decline rapidly. The Mi-Cook pasteurizer effectively kills the bacteria on the product surface.

Mi-Cook are with vacuum packaging products, instead of aseptic packaging products. In the packaging process, bacteria and microorganisms are bound to invade. Therefore, it is particularly necessary to sterilize in a short time, otherwise the product quality will decline rapidly. The Mi-Cook pasteurizer effectively kills the bacteria on the product surface.

The Mi-Cook pasteurizer adopts PID temperature control to ensure that the product is first in, first out, and the sterilization effect is stable.

The pasteurizing section of the Mi-Cook pasteurizer uses a durable solenoid valve to control the steam supply, and the cooling section uses a direct heat-exchanging method. The standard water temperature of the pasteurizing section is controlled between 82℃-85℃, and the temperature difference is controlled within the range of +/-0.5℃.

Current technology cannot completely achieve aseptic in the packaging process unless the workshop is completely cleaned. In any case, the product will be packaged with microorganisms in it. The remaining question now is how to remove bacteria in vacuum packaged products, pasteurization gives the answer.

The V-shaped and wide-angle nozzle keeps the product moving in the water continuously, so that the product does not float on the water surface. The floating of the product itself is inevitable, but the V-shaped and wide-angle nozzle keeps the product walking in the water to achieve good results. The products will not stop, and will not be over-pasteurized, all products will go forward in turn.

(mm)

|

Model |

PS614 |

OS1014 |

PS2017 |

|

Dimension (L*W*H) |

10580 * 1600 * 2214 |

14000 * 2244 * 2214 |

19532 * 2400 * 2120 |

|

Pasteurization section |

|||

|

Time of passing through |

3 to 30 min |

||

|

Pasteurizing temperature |

85℃ |

||

|

Temperature Control |

PID |

||

|

Heat Exchanger |

80Kg/hr,45000 kcal/hr |

140Kg/hr,79000 kcal/hr |

240Kg/hr,139000 kcal/hr |

|

Cooling Section |

|||

|

Time of passing through |

3 to 30 min |

||

|

Cooling Temperature 4-5℃ |

4-5℃ |

||

|

Heat Exchanger |

Brine / 32000 kcal/hr |

Brine / 58000 kcal/hr |

Brine / 108000 kcal/hr |

|

Utilities required in total (including dewatering section) |

|||

|

Steam |

0.5bar * 380Kg/h |

0.5bar * 700Kg/h |

0.5bar * 1300Kg/h |

|

Water |

5500L |

8200L |

14600L |

|

Heat Exchanger |

Brine / 32000 kcal/hr |

Brine / 58000 kcal/hr |

Brine / 108000 kcal/hr |

|

Total KW |

10.73Kw |

14.13Kw |

21.73Kw |

ps:Without notice in case of data updating.

Previous Page

Next Page

Previous Page

Next Page